Metal Injection Molding (MIM)

Metal injection molding (MIM) is a high-tech near net shaping process to mass-produce small metal parts with complex shape, high precision and good performance. It accumulated twenty years of experience with tools designing and machining, self-binder system and advanced debinding-sintering furnace. Stainless steel, low alloy steel, tool steel, heavy alloy, tungsten carbide of MIM parts have high accuracy, intensity and complexity have been widely used in medical, automotive, mechanical and consumer applications. Over 80% of MIM parts exported to abroad, such as Japan, USA and E.U. Micro-MIM factory has certificated with ISO9001/14000, GB/T28001 and TS-16949

Characteristics:

- Greater freedom in shape design

- More homogeneous microstructure, higher density between 95%-100% of theoretical density

- Surface without polishing better than Ra.1.0 tolerance without rework 0.3%-0.5% of blueprint dimensions

- Consistent quality and high production efficiency, raw materials can be reused in mass production, costs can be sharply reduced

Applicable materials:

Iron-base alloy, stainless steel, tool steel, tungsten alloy, hard-metal alloy, magnetic material, Kovar alloy etc.

Applications:

Computer and OA

Hardware, tools

Surgical instruments and Implants

Electronics/communication

Mechanical parts

Medical,Automotive,IT,Consumer applications

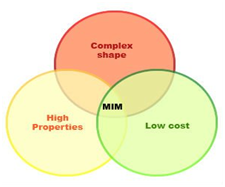

The advantages of MIM